Plain Inside

Our standard solution without internal protection is not suitable for water-based products.

The red compound ensures the tightness of the seam.

The grey compound is particularly performing on solvent-based products and paints.

Doré Inside

Our solution with internal epoxyphenolic protection for water-based products. Also suitable for contact with food.

The red compound ensures the tightness of the seam.

The grey compound is particularly performing on solvent-based products and paints.

Upon Request

The powder coating for the internal protection of the seal provides:

-

excellent resistance to aggressive agents contained in food and sterilization

-

high resistance to solvents

-

FDA compliant product and European regulation for food contact

Transparent Matte Inside

Our solution for maximum internal protection for shaving foam and products for personal use. Also suitable for contact with food.

The red compound ensures the tightness of the seam.

The grey compound is particularly performing on solvent-based products and paints.

Upon Request

The powder coating for the internal protection of the seal provides:

-

excellent resistance to aggressive agents contained in food and sterilization

-

high resistance to solvents

-

FDA compliant product and European regulation for food contact

External finish

-

Plain outside

-

White enamel + gloss or matte finish

Equipped with excellent characteristics of adhesion, flexibility, shine, abrasion resistance and acceptance of traditional and UV-curable inks

-

Lithography

We offer the possibility to all our customers to customize the cans with high quality lithographies and varnishes

External seal protection with nitrogen + protective varnish

Whitening of the welding line with nitrogen to meet high aesthetic requirements

Necked-in Cans

| brimful capacity (ml) | nominal fill (ml) | D mm |

Dn1 mm |

Dn2 mm |

H1 mm |

H2 mm |

H3 mm |

D1 mm |

C mm |

H5 mm |

D2 mm |

|||

| nom | min | max | liquefied gas | compressed gas | ||||||||||

| 110 | 106 | 115 | 75 | - | 45 | 41 | 42 | 78 | 5,6 | 83,6 | 43,6 | 2,9 | 5,3 | 45,2 |

| 140 | 134 | 146 | 100 | 75 | 96 | 101,6 | ||||||||

| 175 | 169 | 181 | 125 | 100 | 118 | 123,6 | ||||||||

| 210 | 204 | 216 | 150 | 125 | 140 | 145,6 | ||||||||

| 270 | 262 | 278 | 200 | 150 | 178 | 183,6 | ||||||||

| 140 | 134 | 146 | 100 | 75 | 52 | 48 | 50 | 72 | 8,0 | 80 | 50,7 | 3,2 | 5,6 | 52,7 |

| 175 | 169 | 181 | 125 | 100 | 88 | 96 | ||||||||

| 210 | 204 | 216 | 150 | 125 | 105 | 113 | ||||||||

| 270 | 262 | 278 | 200 | 150 | 132 | 140 | ||||||||

| 335 | 325 | 345 | 250 | 200 | 161 | 169 | ||||||||

| 405 | 393 | 417 | 300 | 250 | 195 | 203 | ||||||||

| 520 | 507 | 533 | 400 | 300 | 244 | 252 | ||||||||

| 270 | 262 | 278 | 200 | 150 | 57 | 52 | 54 | 110 | 9,5 | 119,5 | 55,5 | 3,3 | 6,0 | 57,6 |

| 335 | 325 | 345 | 250 | 200 | 136 | 145,5 | ||||||||

| 405 | 393 | 417 | 300 | 250 | 164 | 173,5 | ||||||||

| 520 | 507 | 533 | 400 | 300 | 207 | 216,5 | ||||||||

| 650 | 637 | 663 | 500 | 400 | 257 | 266,5 | ||||||||

| 335 | 325 | 345 | 250 | 200 | 65 | 60 | 63 | 105 | 13,5 | 118,5 | 63,2 | 3,3 | 6,3 | 65,9 |

| 405 | 393 | 417 | 300 | 250 | 122 | 135,5 | ||||||||

| 520 | 507 | 533 | 400 | 300 | 157 | 170,5 | ||||||||

| 650 | 637 | 663 | 500 | 400 | 195 | 208,5 | ||||||||

| 800 | 784 | 816 | 600 | 500 | 240 | 253,5 | ||||||||

| 1000 | 980 | 1020 | 750 | 600 | 300 | 313,5 | ||||||||

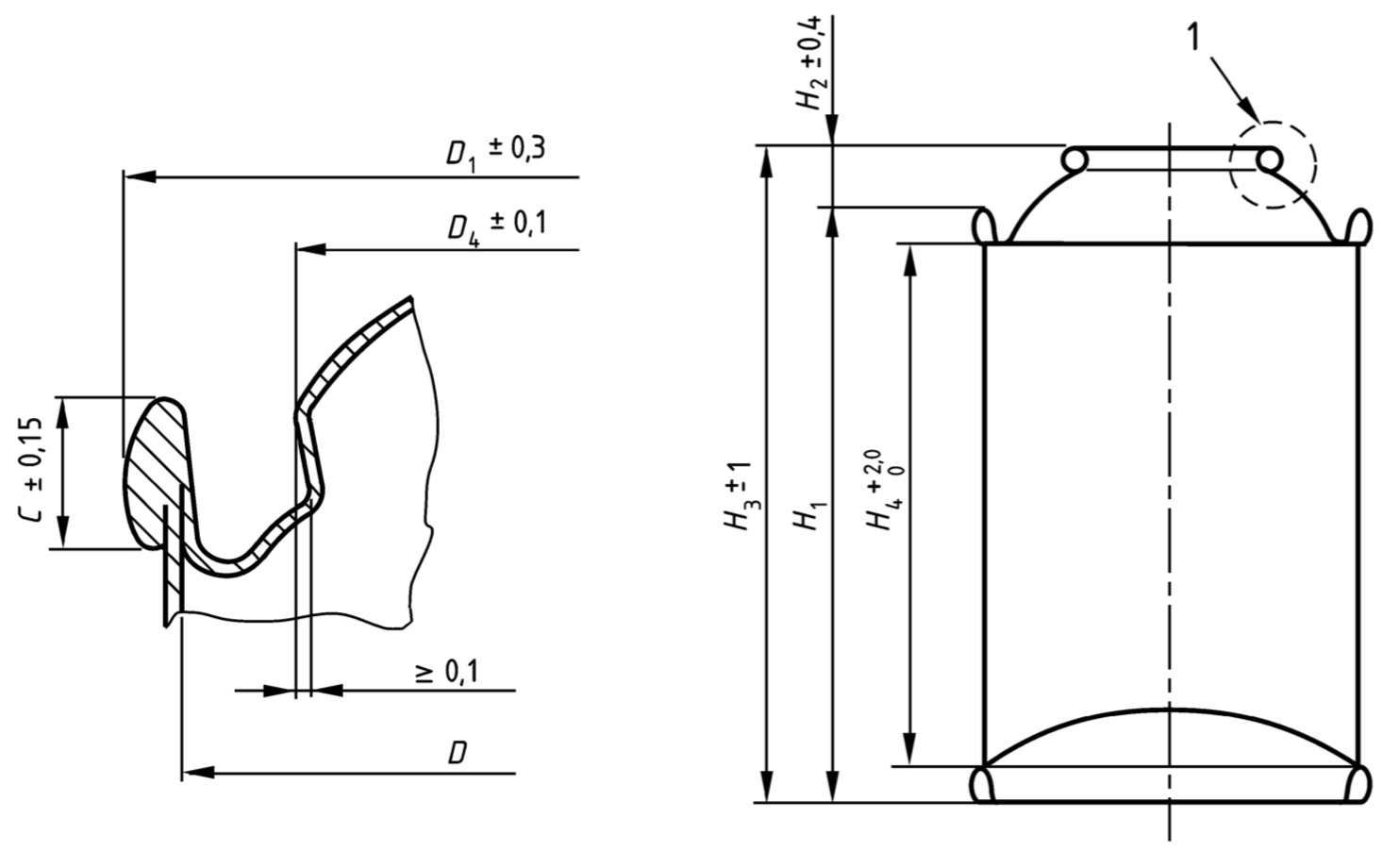

Straight Cans

| brimful capacity ml | nominal fill ml | D mm |

D1 mm |

H1 mm |

H2 mm |

H3 mm |

D2 mm |

C mm |

H4 mm |

D4 mm |

|||

| nom | min | max | liquefied gas | compressed gas | |||||||||

| 335 | 325 | 345 | 250 | 200 | 65 | 68,7 | 105 | 15,5 | 120,5 | 65,9 | 3,3 | 98 | 58,5 |

| 405 | 393 | 417 | 300 | 250 | 195 | 204,5 | 188 | ||||||

| 520 | 507 | 533 | 400 | 300 | 157 | 172,5 | 150 | ||||||

| 650 | 637 | 663 | 500 | 400 | 195 | 210,5 | 188 | ||||||

| 800 | 784 | 816 | 600 | 500 | 240 | 255,5 | 233 | ||||||